ENTRY 8:

The beauty is in the process. One that has been cultivated since 1895. Discover the unparalleled beauty of our tools.

THE

TOOLS

For centuries, our maestros are specialized according to the different forms of the piece they must create. Some forms, even those that do not appear particularly complex, require passing through several hands.

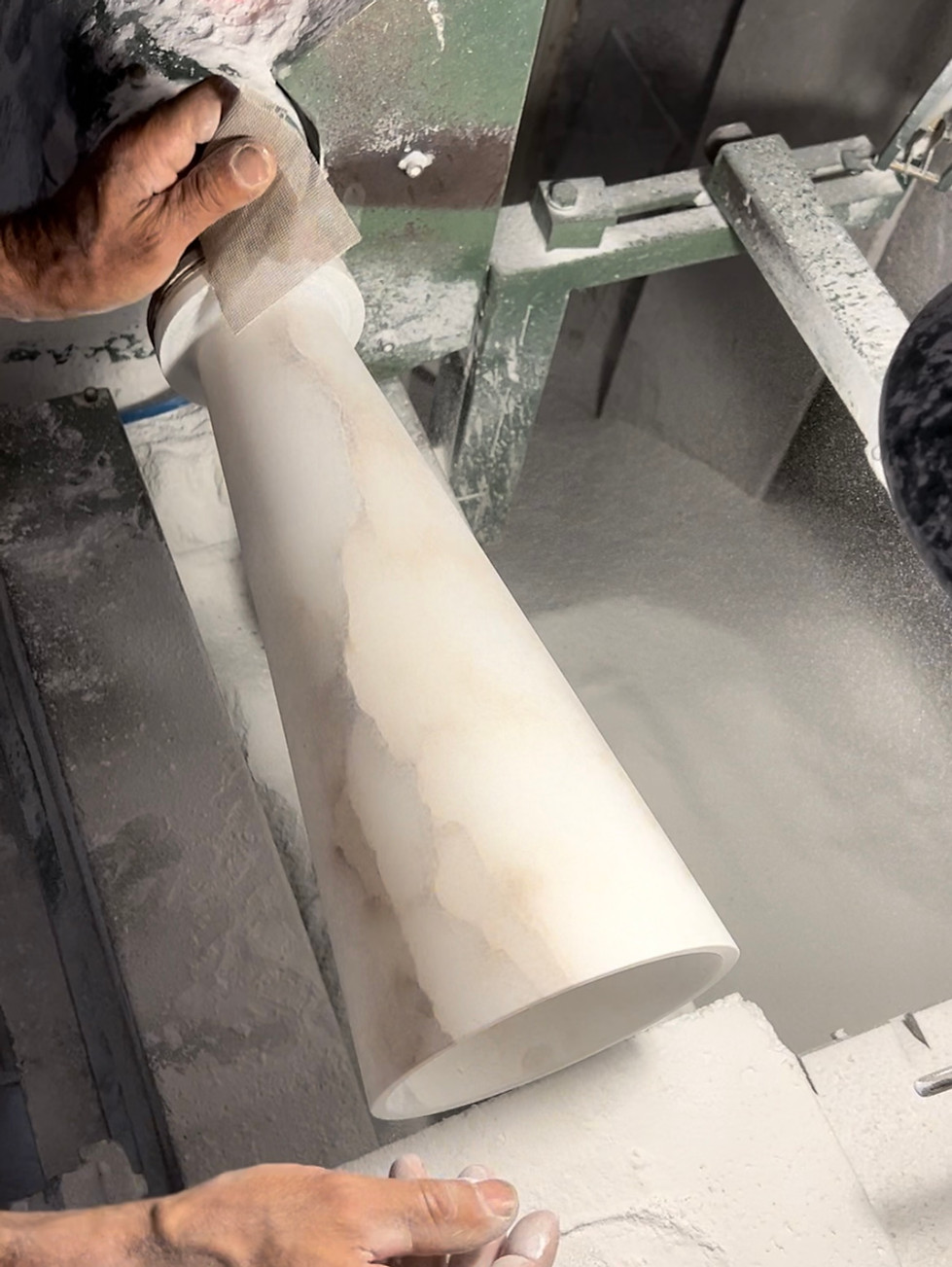

The Tornitori artisans create our round or spherical objects on the lathe for our Trento, Lucca, Domo, Nova, and Porta collections.

Each piece is meticulously turned from 6 million year old solid stone. After preparing a cylinder of the material, they attach the form to a lathe’s axis to carve using a “rampini” and measure the thicknesses with a “tente.”

The skill lies in removing the interior material while preserving as much of the solid alabaster stone as possible.

There are only 17 maestros in the world. 15 of them are making your Orphan Work lights. These awards are from the Italian government and further solidify their status in the artisan world. To achieve this they must go through a rigorous set of curriculum of skill and knowledge. A steadfast commitment ingrained in passing down the wealth of craft knowledge to ensure its legacy.

.jpg)

The piece is then detached with a special tool a delicate step that requires generations of knowledge and attention as fragile pieces often break during removal.

.jpg)

The Squadratori artisans create the square forms of our Ponti and Lastra collections.

They use horizontal dragging saws to cut blocks into slabs by hand, then transfer measurements using a “seste,” a type of measuring compass.

The Sculptors specialize in highly detailed forms working from drawings or plaster models as seen in our Siena and Vara collections. Using a pantograph, they transfer measurements and then sculpt with rasps, irons, and scuffine.

The Ornatisti specialize in ornamentation in low or high relief, using “scuffine” and “ferri,” as seen on our Roma collection.

Glossary of Tools.

Scuffine: small chisels or gouges used for engraving and detailing.

Ferri a forza: heavy irons for removing large amounts of material.

Ferri a mano: lighter hand tools for delicate carving.

Rampini: hook-shaped tools used on the lathe for hollowing.

Tente: calipers for measuring thicknesses on the lathe.

Seste: large compasses for tracing measurements.

Sega a svoltino: a narrow curved-blade saw for cutting curved shapes.

Today, following traditional principles, dipesciatura is done manually, slowly,

by hand with fine sandpapers.

Sprellatura is performed with a rotating brush applied with triplo, a paste of powdered shells and crustaceans.

The utmost care must be taken to avoid overheating, which causes ingessire, or loss of transparency. Polishing is done with a soft brush and lustro, a fine abrasive powder resembling chalk.

What makes our alabaster truly distinct,

is that we retain the natural qualities of the stone. Using only natural materials when hand finishing.

Polishing is one of the most fascinating and misunderstood aspects of alabaster work. Since the 1950s, many pieces have been coated in synthetic polyester resins, which are inexpensive, glossy, and waterproof but prevent the alabaster from breathing, aging naturally, and showing its transparency, veining, and color. Polyester often yellows over time.

Instead, our alabaster is finished by slowly heating it over embers and coating it with “sparmaceto,” our custom mixture of oil, wax, and tallow. Multiple applications are used until our iconic shine and softness is perfect, and is followed by cotton buffing using cloths that have been passed down through generations.

Discover more of our 'Made in Italy' story.

TO THE

TRADE

A beautiful, authentic way to stay connected and inspired together.

As a member of our trade program you'll be the first to know about new arrivals from Italy, as well as get a note from the studio or our artisans.

It's a really special look inside our Made in Italy story.